Industrial

Optimized Lubrication for Industrial Equipment

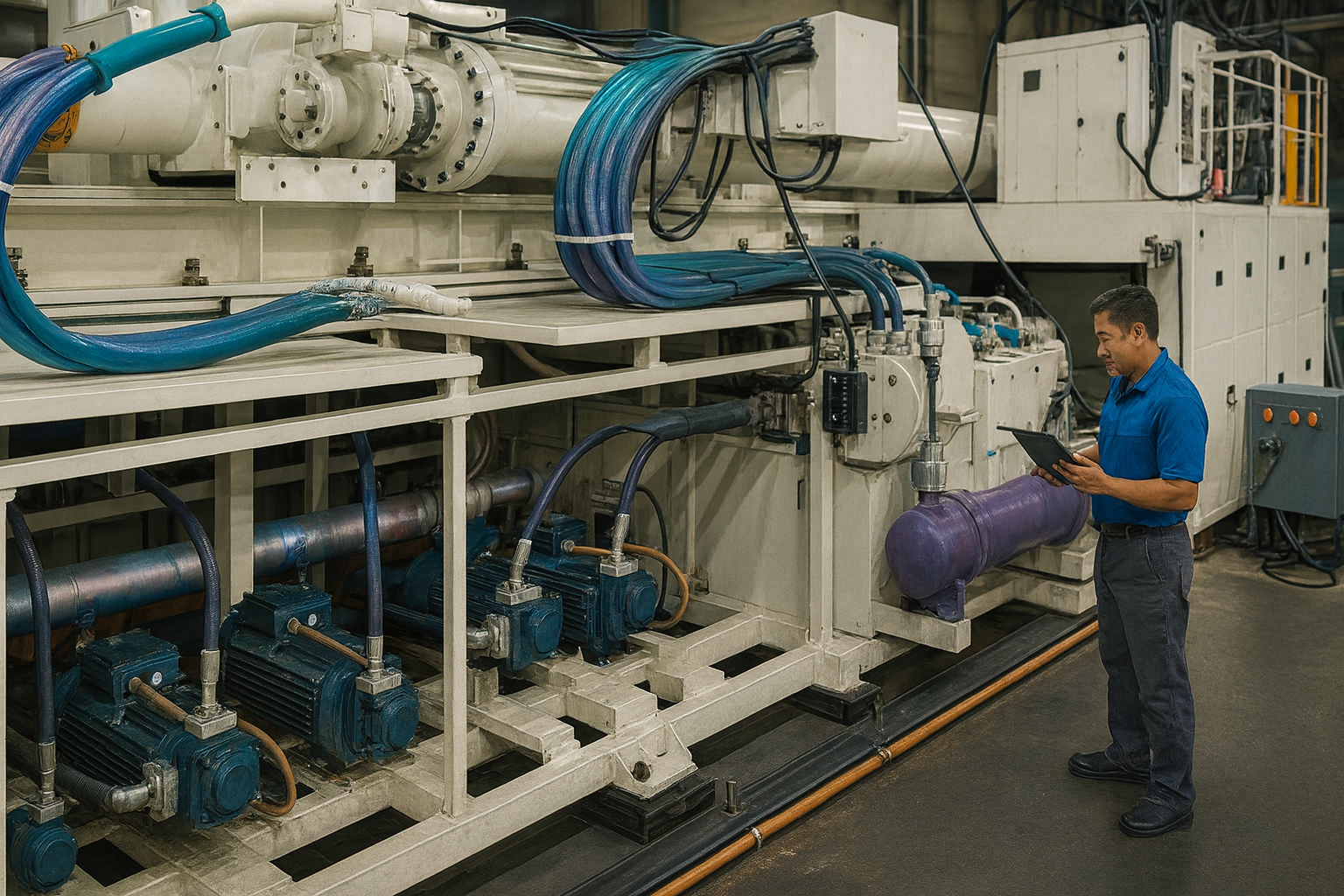

Plastics

Mobil industrial lubricants protect plastics processing equipment— Hydraulics, gearboxes, and bearings—from wear and deposits. They ensure smooth operation, reduced downtime and consistent product quality in competitive manufacturing. High-performance formulations support precision, efficiency and extended equipment life.

Textile

Textile-grade industrial lubricants are designed to perform in high-speed, dusty and humid conditions. They help protect bearings and gears, reduce unplanned stoppages and support stable fabric quality across spinning, weaving and finishing

Machining

Advanced cutting and grinding fluids help improve tool life, surface finish and dimensional accuracy in modern machine shops. They support cleaner operation, lower coolant-related maintenance and more consistent productivity.

Cement

Cement plants operate heavy equipment in dusty, high-temperature quarry and kiln environments with extreme shock loads. Specialized Mobil lubricants protect crushers, mills, kilns and conveyors, extending component life and minimizing downtime. This ensures continuous production, reliable performance and lower maintenance costs.

Steel

Industrial lubricants for steel and metal processing protect equipment operating under extreme temperatures, heavy loads and wet conditions. They help reduce wear, support cleaner systems and improve line reliability

Paper Industry

High-performance oils and greases help protect bearings, gears and circulating systems on paper machines. They support clean operation, better water and deposit control, and more consistent sheet quality

Mobile Equipment

Lubricants for mobile and off-highway fleets protect engines, transmissions, final drives and hydraulics in tough conditions. They help reduce wear, extend service intervals and support reliable, fuel-efficient operation.

Mining

Mining lubricants are engineered for equipment facing dust, shock loads and harsh environments. They help protect critical components, support extended service intervals and contribute to safer, more productive operations.

Hydraulics

Mobil hydraulic lubricants optimize system productivity and lower energy consumption. Anti-wear hydraulic oils protect pumps and valves, resist sludge/varnish, and maintain stable viscosity for energy-efficient operation. They deliver precise control, extended oil life and reliable performance while reducing power losses.

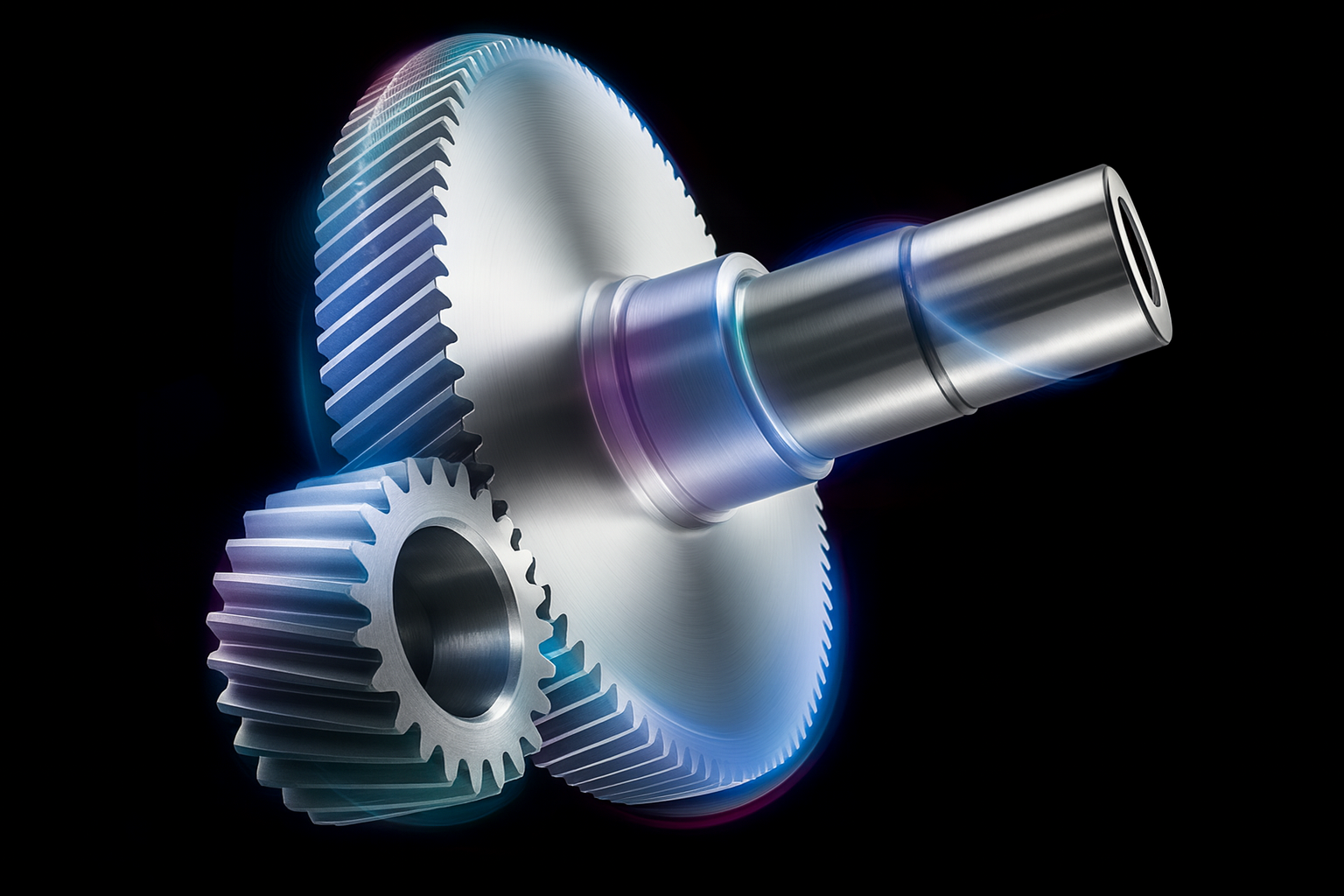

Gears

Mobil™ gear oils carry high loads, resist micropitting and manage moisture for reliable performance. They extend gear and bearing life while enabling efficient, quiet power transmission. Advanced formulations reduce wear and maintain efficiency in demanding conditions.

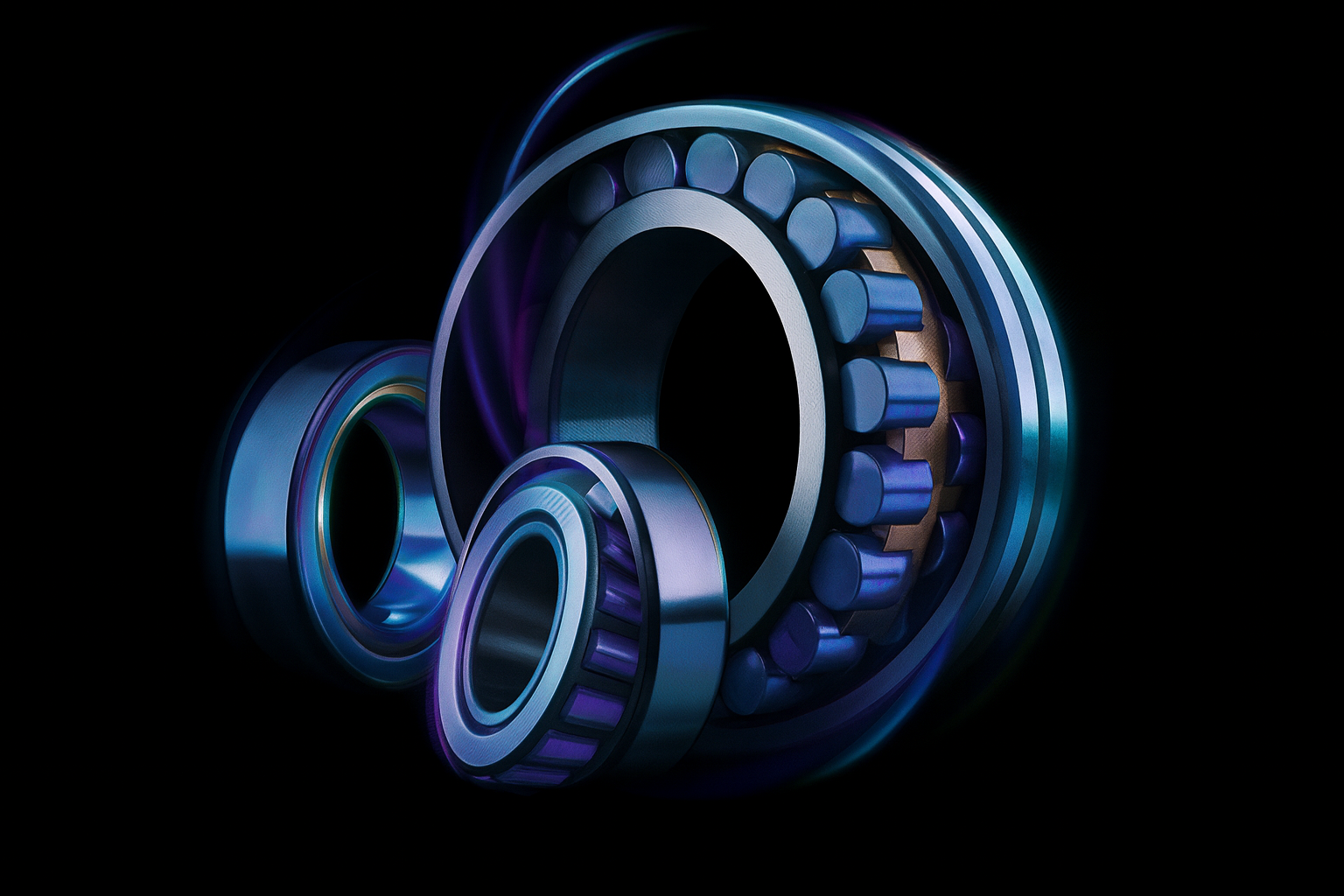

Bearings

Mobil bearing lubricants perform reliably across varied speeds, loads, temperatures and conditions. The right grease and relubrication practice minimize wear, friction and heat rise for smoother operation. This extends bearing life, improves equipment reliability and reduces maintenance needs.

Grease

Grease lubricants are designed to protect equipment operating under varying loads, speeds, and environments. Proper grease selection helps reduce wear, resist contamination, prevent leakage, and ensure reliable performance and extended service life for critical components.

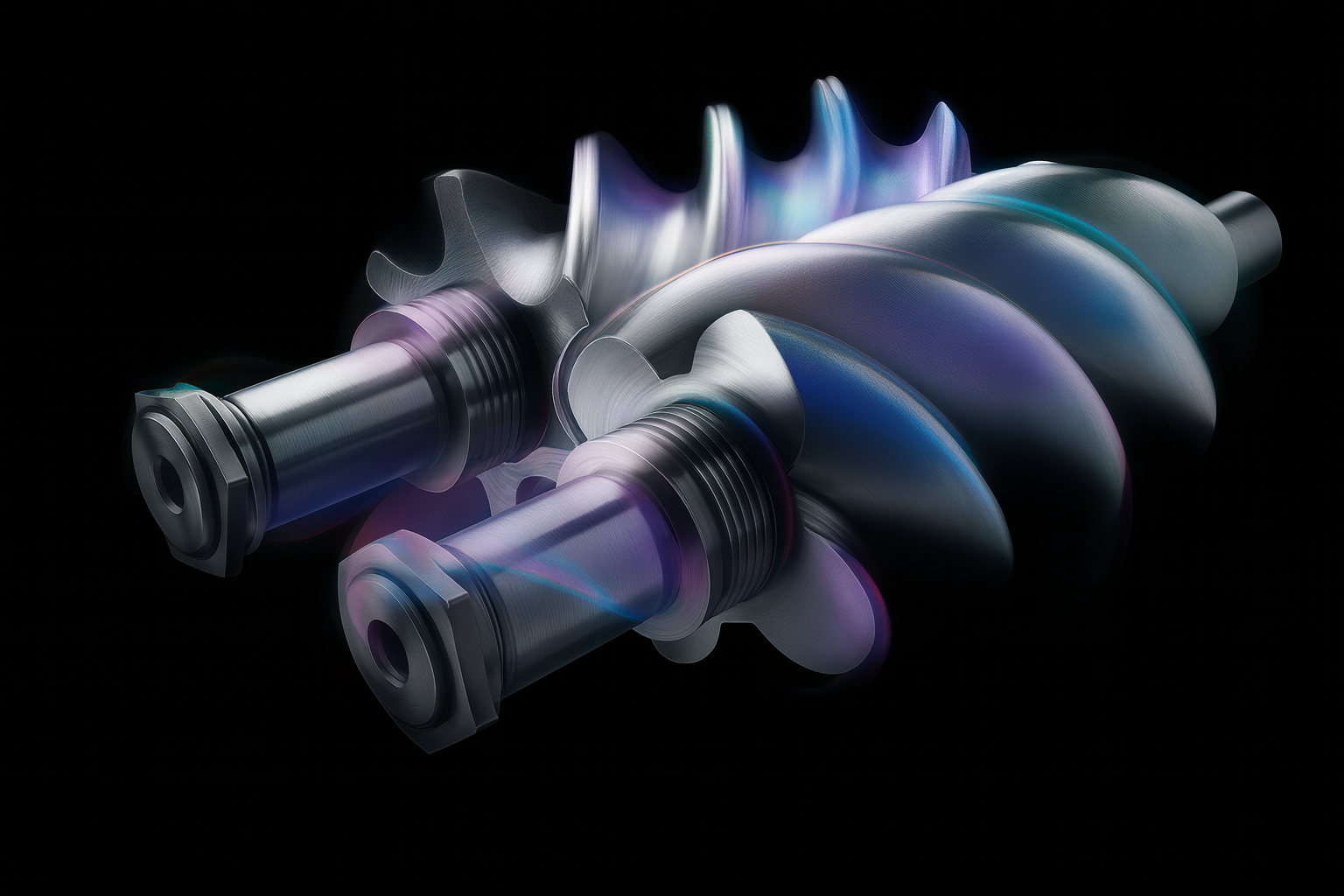

Air Compressor

The right air compressor lubricant plays a key role in improving performance, reliability, and service life. Mobil compressor oils help ensure smooth operation across temperature extremes while reducing wear, deposits, and maintenance needs

Refrigeration compressors

Selecting the right lubricant for the right application is essential, especially in systems using natural refrigerants like ammonia and CO₂. Specialized lubricants are designed to address compatibility challenges and support reliable performance under evolving regulatory and operating conditions

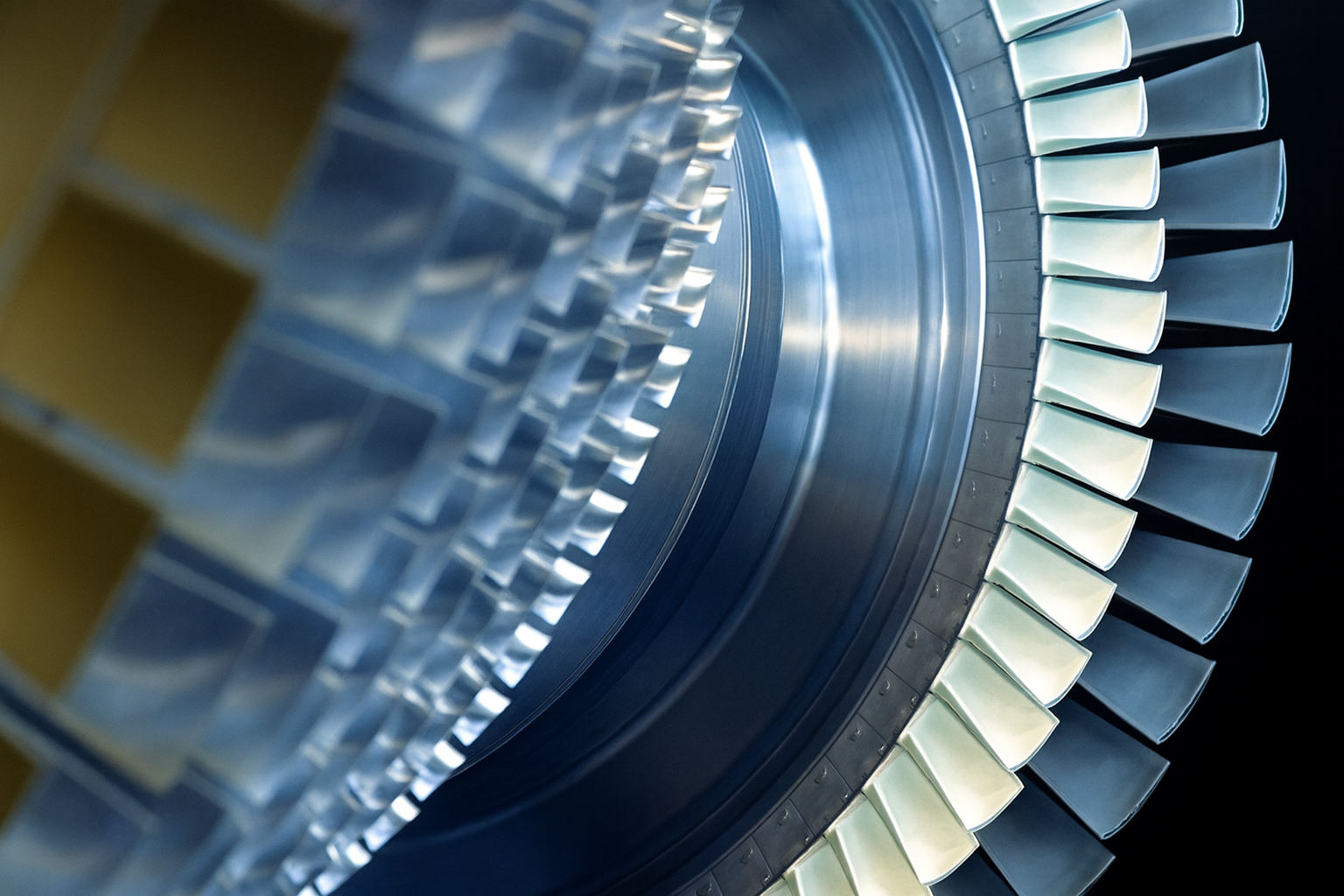

Turbine

Mobil turbine oils deliver excellent oxidation stability and deposit control for steam and gas turbines. They protect bearings and control systems, supporting fast startups, long oil life and reliable operation. Proper selection ensures efficiency and performance under demanding, continuous conditions.

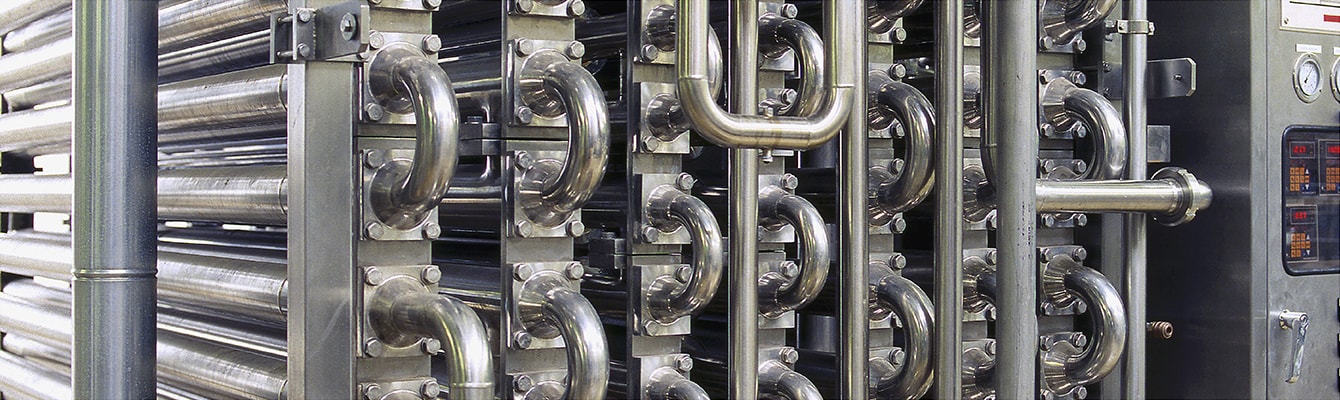

Heat Transfer oils

Heat transfer fluids with strong thermal stability help maintain heat exchange efficiency and reduce fouling. They support consistent process temperatures and longer system life.

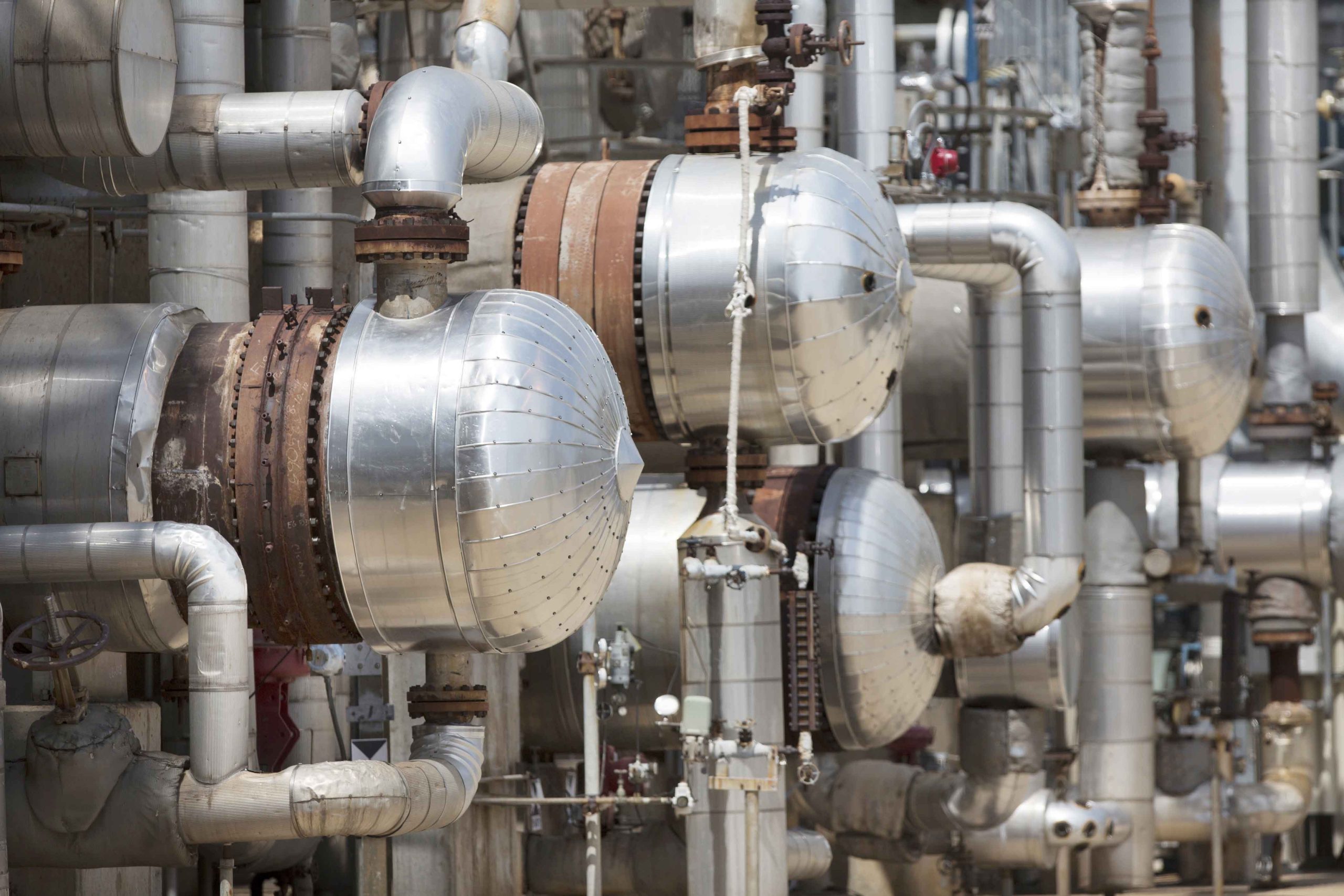

Energy

Lubricants for power generation protect turbines, gearboxes and auxiliary systems running under continuous, high-load conditions. They help reduce outages, extend component life and support overall plant efficiency

Gas Engine Oil

Gas engine oils are formulated to protect engines operating on natural gas and other gaseous fuels. They help control deposits, neutralise acids, reduce wear, manage heat, and support reliable performance, efficiency, and extended engine life under continuous-duty conditions.

Food

Food-grade lubricants help protect equipment while supporting food safety standards in processing and packaging lines. They offer strong wear and corrosion protection in applications where incidental contact can occur.

Explore Our Recommended Equipment Builders