Tyre Service

Tyre Retreading Process Flow

Inspection

Inspection is the first step in the tyre retreading process, where each tyre is carefully examined for damage, casing condition, and safety limits. Only tyres that meet quality standards are approved for retreading to ensure reliability and performance.

Buffing

Buffing prepares the tyre casing by removing worn tread and creating a smooth, uniform surface. This process ensures proper bonding of the new tread, improves adhesion, and helps achieve consistent performance and durability.

Rasping

Rasping is a tyre retreading step that smoothens and textures the casing surface after buffing. It helps correct surface irregularities, improves tread bonding, and ensures uniform contact for strong, reliable retread performance.

Solutioning

Solutioning is a tyre retreading process where a bonding solution is applied to the prepared casing. It activates the rubber surface, improves adhesion between components, and ensures strong, uniform bonding during tread building and curing.

Filling

Filling is a tyre retreading step where skived or damaged areas of the casing are filled with repair rubber. This restores casing shape and strength, ensures a smooth surface, and supports safe, durable tread bonding during curing.

Building

Building is the stage in tyre retreading where new tread rubber is carefully applied to the prepared casing. Precise alignment and placement ensure uniform tread thickness, strong bonding, and reliable performance over extended service life.

Curing

Curing bonds the new tread permanently to the tyre casing using controlled heat and pressure. This process ensures proper adhesion, restores tyre strength, and delivers a durable tread designed for reliable performance and extended service life.

Finished tyre

The finished tyre undergoes final inspection to verify tread quality, bonding strength, and overall safety. Only tyres that meet required standards are approved for use, ensuring reliable performance, durability, and road readiness.

PRODUCTS

Precured tread rubber

Precured tread rubber is used in tyre retreading to restore worn tyres with consistent tread patterns and reliable performance. It offers strong bonding, uniform wear, improved mileage, and durability, making it a cost-effective and sustainable retreading solution.

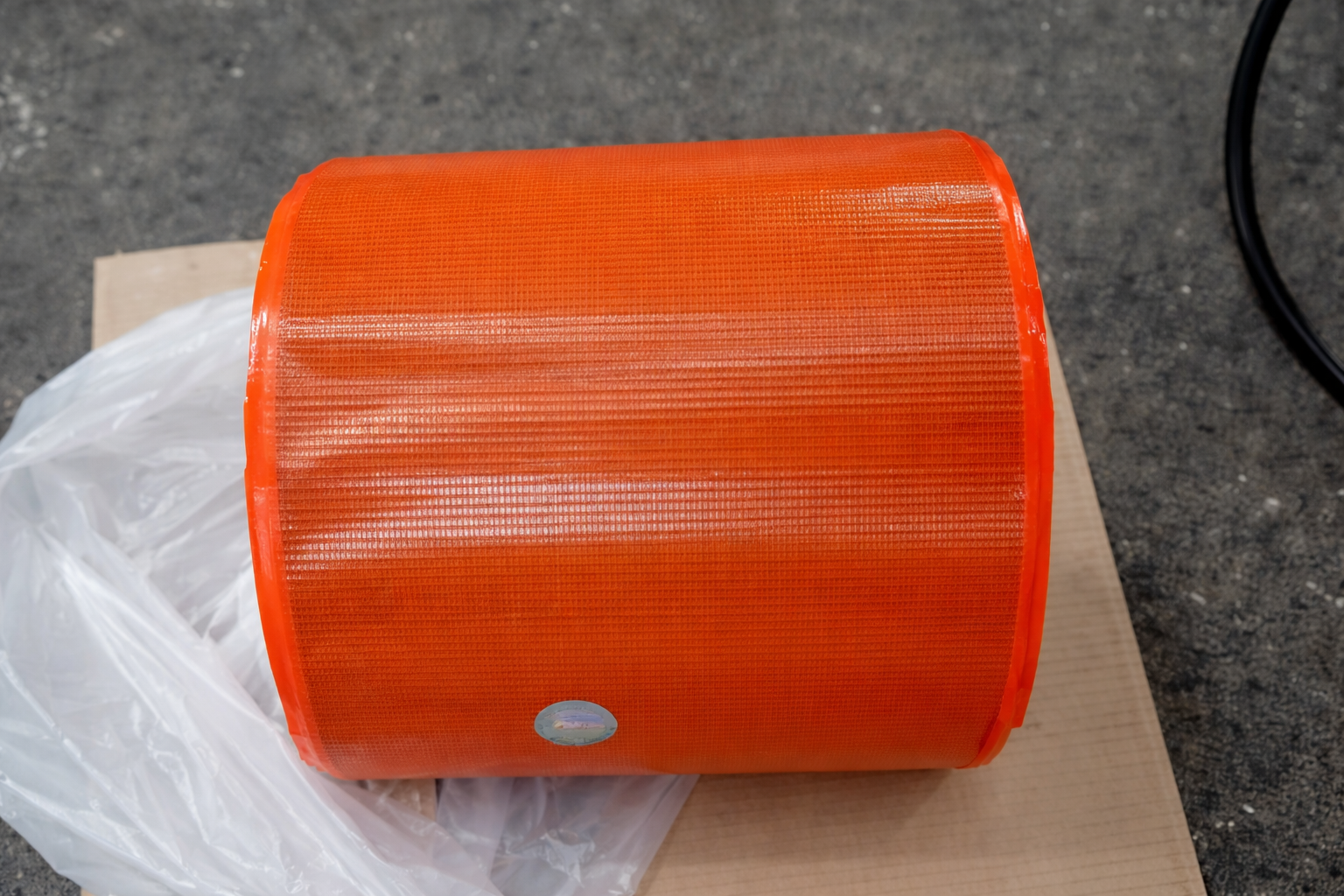

Full skirt envelopes

Full skirt envelopes are used in tyre retreading to fully wrap the tyre casing, ensuring uniform pressure during curing. This design improves tread bonding, shape consistency, and overall durability, resulting in reliable performance and extended tyre life.

Unvulcanised rubber strip gum

Unvulcanised rubber strip gum is used in tyre retreading to repair injuries and fill skived areas in the casing. It ensures strong bonding during curing, restores casing integrity, and supports safe, durable retread performance.

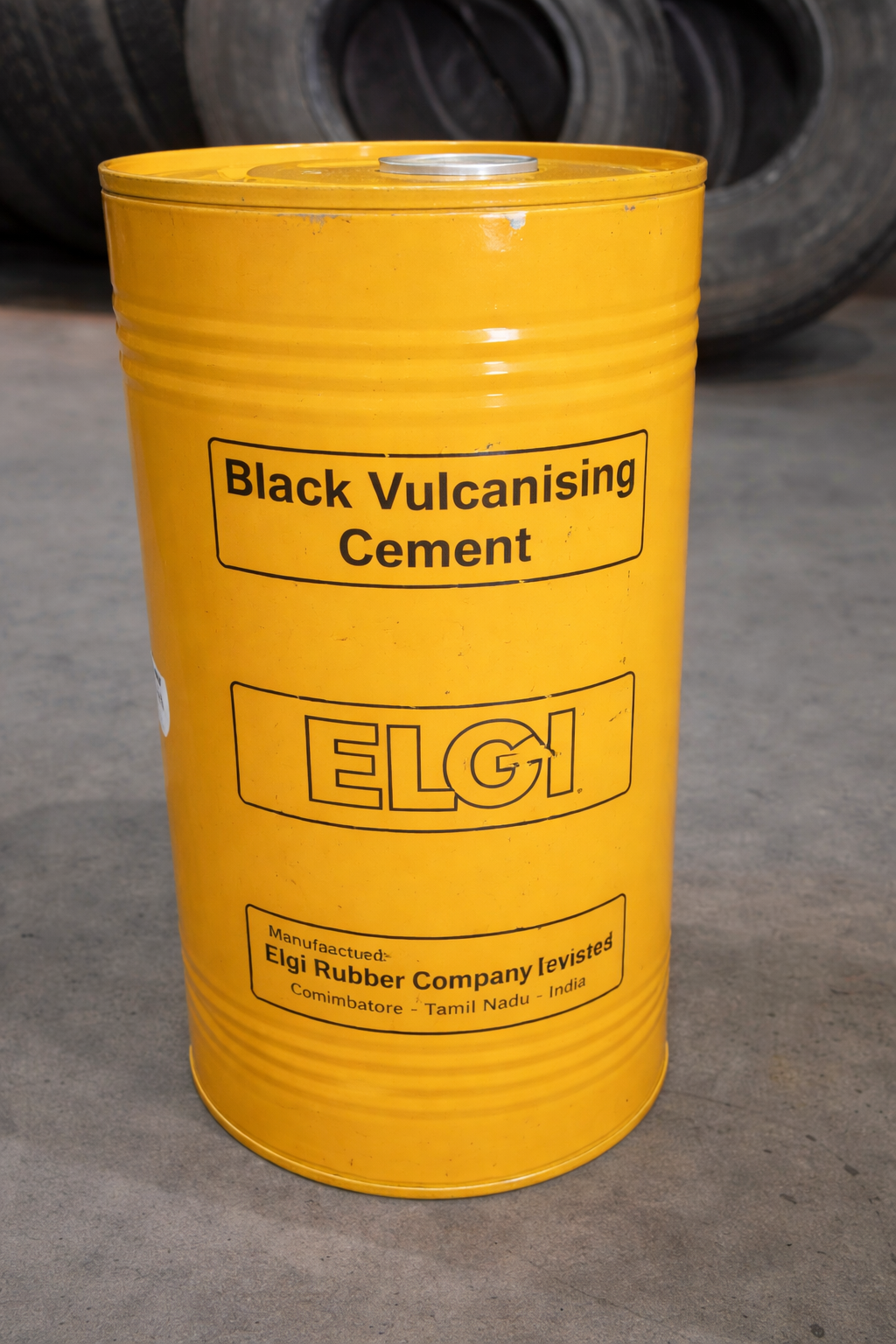

Black Vulcanising Cement

Black Vulcanising Cement is used in tyre retreading to provide quick, uniform bonding between rubber components and casings. It improves adhesion during building, enhances process efficiency, and supports consistent tread application and curing results.

CVC

CVC is used in tyre retreading to ensure uniform application of bonding cement on the casing surface. Controlled cementing improves adhesion, reduces material waste, and supports consistent tread bonding for reliable retread quality.

Tread Box

Tread boxes are used in tyre retreading to store, organize, and handle precured tread rubber safely. They protect tread material from damage and contamination, maintain product quality, and support smooth, efficient workflow during the retreading process.

Bonding GUM

Bonding gum is used in tyre retreading to create a strong bond between the tread rubber and the tyre casing. It fills surface irregularities, improves adhesion during curing, and ensures durable, reliable retread performance.

Tyre Aqua Coat

Tyre aqua coat is applied during retreading to seal the tyre surface and protect it from moisture and contamination. It improves appearance, supports curing performance, and helps maintain tyre quality during handling and storage.